Manufacturing technology has come a long way in recent years, and there are now a variety of new innovations that are transforming the industry. From 3D printing to artificial intelligence, these technologies are helping manufacturers to create better products, streamline processes, and improve efficiency. In this article, we’ll take a look at the top manufacturing technology innovations you need to know about.

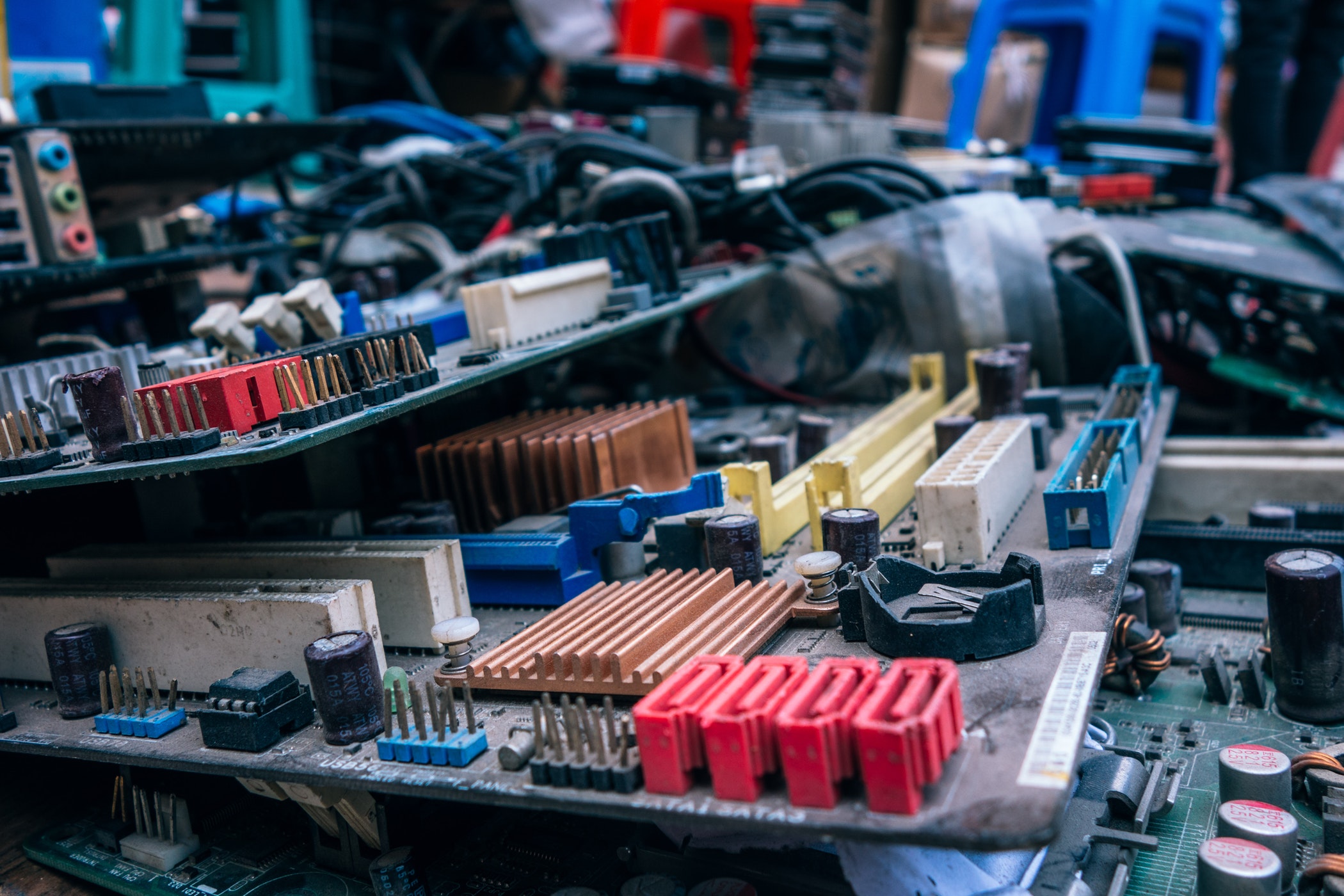

3D Printing

Source: bing.com

Source: bing.com3D printing has been around for a few years now, but it is still one of the most exciting and promising manufacturing technologies out there. With 3D printing, manufacturers can create complex shapes and designs that would be impossible with traditional manufacturing techniques. This technology is particularly useful for creating prototypes, as it allows designers to quickly create and test new concepts before committing to a full-scale production run.

Artificial Intelligence

Source: bing.com

Source: bing.comArtificial intelligence (AI) is another technology that is transforming manufacturing. With AI, manufacturers can automate many of their processes, from production to quality control. This not only speeds up production times, but also reduces the risk of human error. AI can also be used to analyze data and identify patterns, which can help manufacturers to optimize their processes and improve efficiency.

Internet of Things

Source: bing.com

Source: bing.comThe Internet of Things (IoT) is a network of connected devices that can communicate with each other and exchange data. In manufacturing, IoT devices can be used to monitor machines and equipment, track inventory, and even monitor employee productivity. This technology can help manufacturers to identify potential issues before they become major problems, and can also help to reduce downtime and improve efficiency.

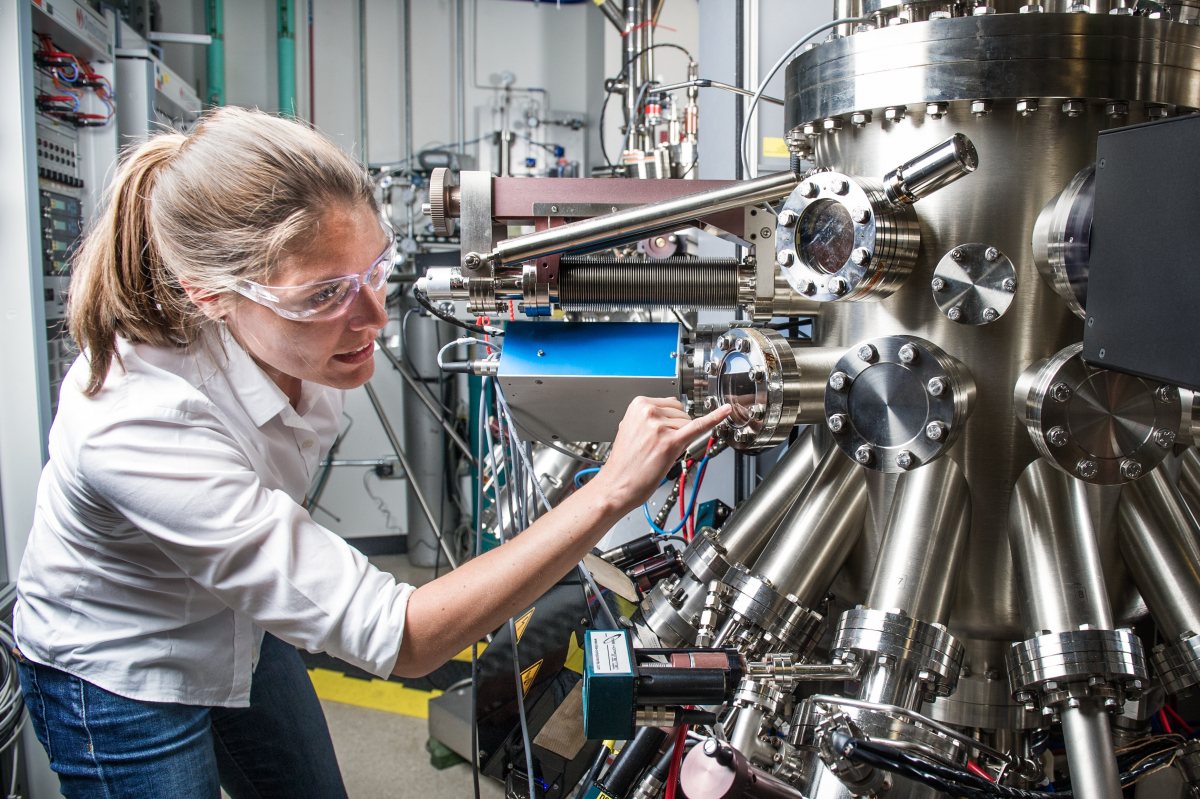

Robotics

Source: bing.com

Source: bing.comRobotics is another technology that is revolutionizing manufacturing. With robotics, manufacturers can automate many of their processes, from assembly to packaging. This not only speeds up production times, but also reduces the risk of human error. Robotics can also be used to perform tasks that are too dangerous or difficult for humans to do, such as working with hazardous materials or in extreme temperatures.

Augmented Reality

Source: bing.com

Source: bing.comAugmented reality (AR) is a technology that overlays digital information onto the real world. In manufacturing, AR can be used to provide workers with real-time information and instructions, such as how to assemble a product or perform a maintenance task. This can help to reduce errors and improve efficiency, as workers can quickly access the information they need without having to consult manuals or other resources.

Big Data

Source: bing.com

Source: bing.comBig data is a term used to describe the vast amounts of data that are generated by businesses and organizations. In manufacturing, big data can be used to monitor production processes, track inventory, and analyze customer behavior. By analyzing this data, manufacturers can identify trends and patterns, which can help them to optimize their processes and improve efficiency. Big data can also be used to improve product design, by providing insights into how customers use and interact with products.

Blockchain

Source: bing.com

Source: bing.comBlockchain is a technology that is often associated with cryptocurrency, but it has many applications beyond that. In manufacturing, blockchain can be used to create a secure and transparent supply chain. By using blockchain, manufacturers can track products from the raw materials stage all the way to the finished product, ensuring that every step of the process is recorded and verified. This can help to reduce the risk of fraud and counterfeiting, and can also provide customers with greater transparency and confidence in the products they buy.

Cybersecurity

Source: bing.com

Source: bing.comCybersecurity is a critical concern for all businesses, and manufacturing is no exception. With so many connected devices and networks, manufacturers are at risk of cyber attacks that could compromise their data and operations. By implementing strong cybersecurity measures, such as firewalls, encryption, and employee training, manufacturers can reduce their risk of cyber attacks and protect their business.

Digital Twins

Source: bing.com

Source: bing.comFinally, digital twins are a technology that is gaining popularity in manufacturing. A digital twin is a virtual replica of a physical object or process, created using data from sensors and other sources. This technology can be used to simulate production processes and test new designs before they are implemented in the real world. By using digital twins, manufacturers can reduce the time and cost of testing and prototyping, and can also improve the accuracy of their simulations.

Manufacturing technology is constantly evolving, and these are just a few of the many innovations that are transforming the industry. By staying up-to-date with the latest technologies and trends, manufacturers can improve their processes, create better products, and stay ahead of the competition.

Related video of The Top Manufacturing Technology Innovations You Need to Know About

DAFTAR ISI

Majalah Pulsa Kumpulan Berita dan Informasi Seputar Teknologi

Majalah Pulsa Kumpulan Berita dan Informasi Seputar Teknologi