Source: bing.com

Source: bing.comIndustrial Internet of Things (IIoT) is an innovative technology that allows factories and other industrial facilities to connect their machines, equipment, and devices to the internet. This technology has revolutionized the way industries operate by enabling automation and data exchange between machines. In this article, we will discuss the benefits of using industrial IoT for factory automation.

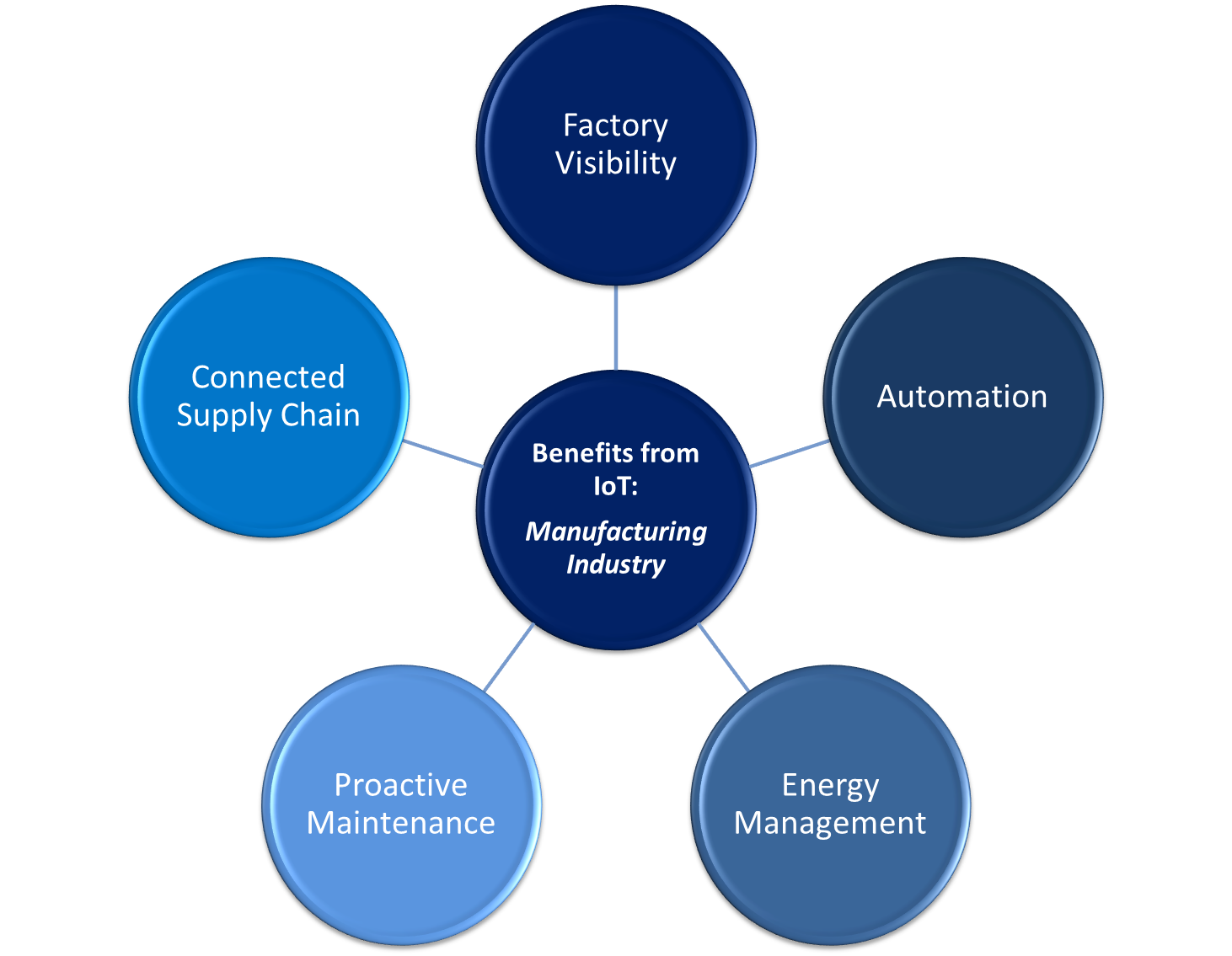

1. Increased Efficiency

Source: bing.com

Source: bing.comThe deployment of IIoT in factory automation can significantly improve efficiency by automating critical processes, reducing downtime, and streamlining workflows. By connecting machines to the internet, factory owners can monitor and analyze data in real-time, enabling them to identify inefficiencies and optimize production processes. This, in turn, improves productivity and reduces overhead costs.

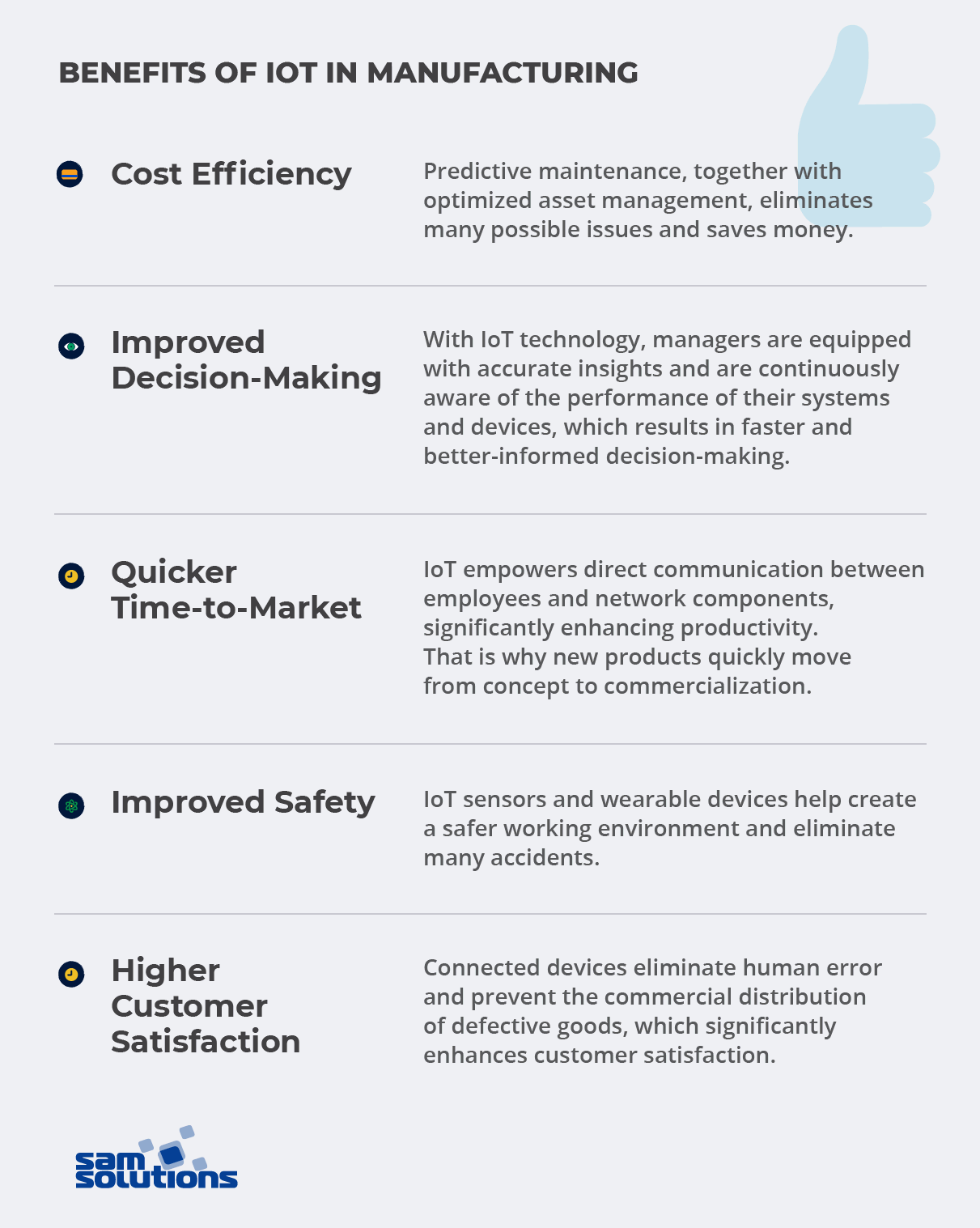

2. Predictive Maintenance

Source: bing.com

Source: bing.comIIoT technology enables factory owners to predict when maintenance is required, eliminating the need for manual inspections. By analyzing data from sensors and other connected devices, factory owners can detect potential issues before they occur, allowing them to take preventive measures. This ensures that machines are maintained in good working condition, reducing downtime and improving productivity.

3. Improved Safety

Source: bing.com

Source: bing.comFactory automation using IIoT can improve safety by monitoring machines and equipment in real-time. By monitoring data from sensors, factory owners can detect potential safety hazards and take corrective measures before accidents occur. This ensures that workers are safe and reduces the risk of accidents in the workplace.

4. Reduced Energy Consumption

Source: bing.com

Source: bing.comIIoT technology can also help reduce energy consumption in factories and industrial facilities. By analyzing data from sensors and other connected devices, factory owners can identify energy inefficiencies and take corrective measures. This can involve turning off machines when not in use or optimizing the production process to reduce energy consumption. This, in turn, reduces energy costs and contributes to environmental sustainability.

5. Increased Product Quality

Source: bing.com

Source: bing.comIIoT technology can also improve product quality by monitoring machines and equipment in real-time. By analyzing data from sensors, factory owners can detect product defects early and take corrective measures. This ensures that products are of high quality, reducing the risk of product recalls and improving customer satisfaction.

6. Real-Time Data Analysis

Source: bing.com

Source: bing.comIIoT technology enables factory owners to monitor and analyze data in real-time, providing them with valuable insights into production processes. By analyzing data from sensors and other connected devices, factory owners can identify inefficiencies, optimize production processes, and make data-driven decisions. This ensures that factories are operating at peak efficiency and reduces the risk of downtime.

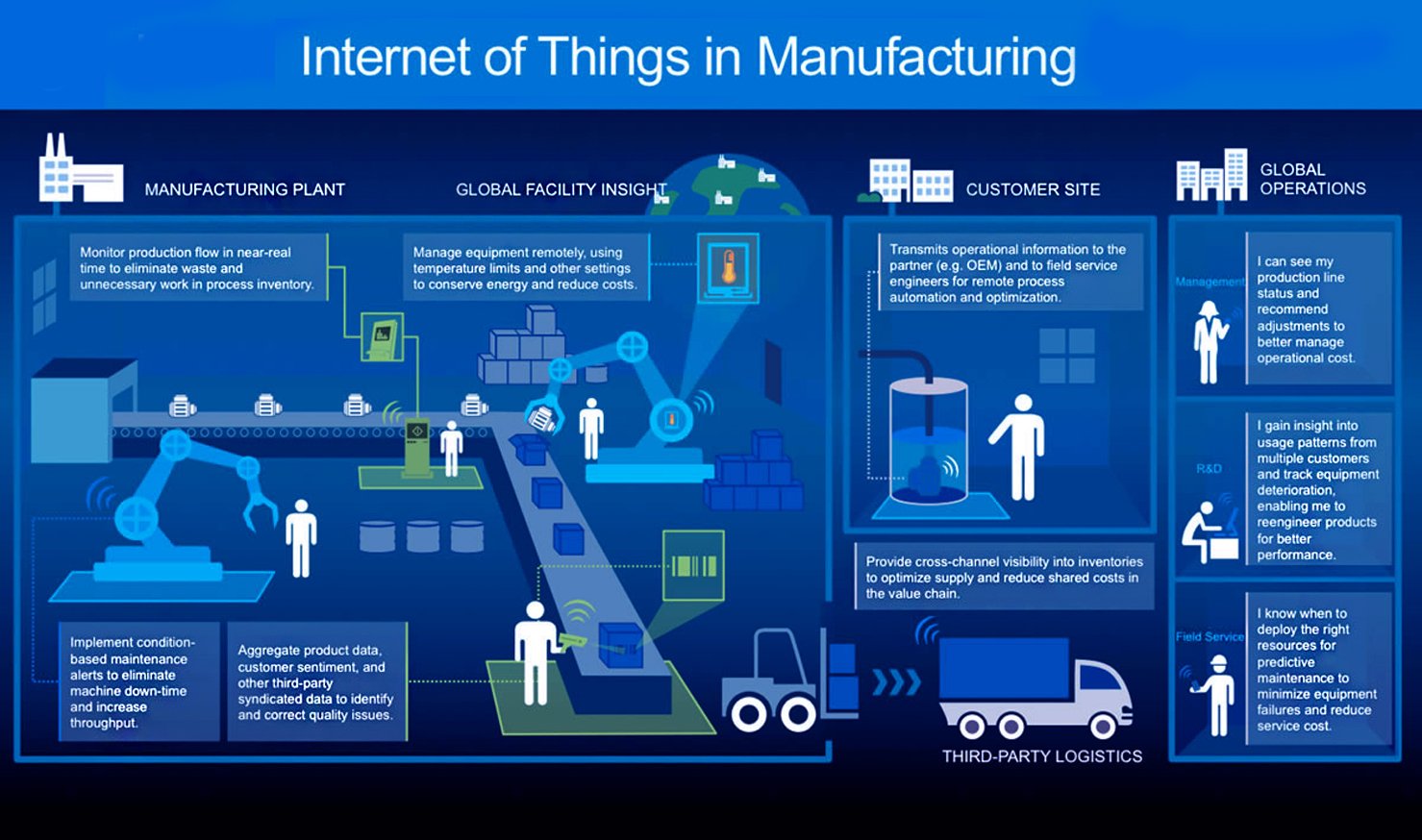

7. Remote Monitoring and Control

IIoT technology enables factory owners to remotely monitor and control machines and equipment. By connecting machines to the internet, factory owners can monitor their operations from anywhere in the world, enabling them to take corrective measures when necessary. This ensures that factories are operating at peak efficiency and reduces the risk of downtime.

Conclusion

Factory automation using IIoT technology offers significant benefits, including increased efficiency, predictive maintenance, improved safety, reduced energy consumption, increased product quality, real-time data analysis, and remote monitoring and control. These benefits can help factories and industrial facilities operate at peak efficiency, reduce downtime, and improve their bottom line. As such, factory owners should consider deploying IIoT technology in their operations to stay competitive in today’s market.

Related video of The Benefits of Using Industrial IoT for Factory Automation

DAFTAR ISI

Majalah Pulsa Kumpulan Berita dan Informasi Seputar Teknologi

Majalah Pulsa Kumpulan Berita dan Informasi Seputar Teknologi